Upon resumption of work, I made note of the fact that

the driver's side header was slightly encroaching on

the space that the C6 transmission would need to be raised

up into. If the passenger side header did the same, it might

be rather difficult to stab the tranny with both headers attached.

So I decided that it was now time to

attach the transmission.

As usual, inserting the torque converter

into the front pump

and lining up the splines and flats

brought sweat to my brow

and curses to my lips (if you've ever

had to do it before,

you know what I mean). Finally, I got

the torque converter

in and wheeled the tranny over to the

car.

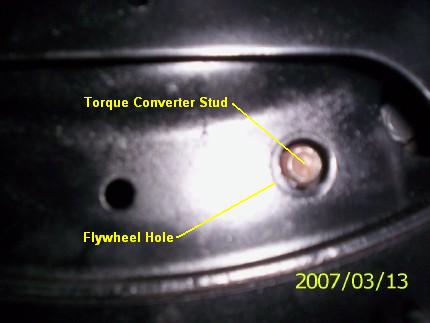

After lifting the transmission into

position, I lined up the torque

converter studs with the flywheel holes.

Everything looked

dead center and ready to stab.

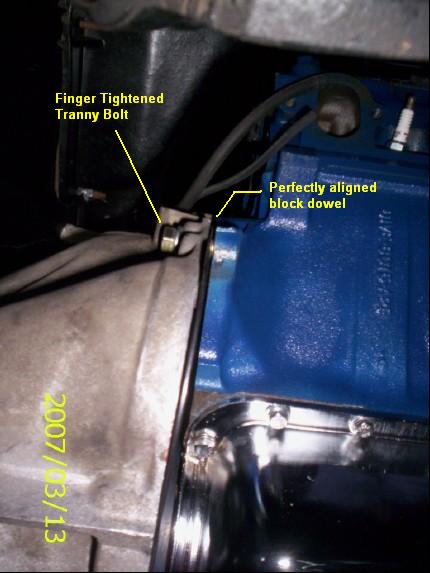

Looked good to me. So did the block

dowels. So I finger

tightened the tranny bolts and proceeded

to try to mate

the transmission to the engine.

After numerous attempts at pushing them

together (to no avail)

I should have realized that

something was rotten in Denmark.

Should have, but didn't;

therefore I did a no-no: I attempted to

pull them together by gently tightening

the bell housing bolts.

When this didn't work, I should have

stopped right there and

dropped the tranny to do some of that

deductive reasoning

that Sherlock Holmes was always chattering

about; should have

but didn't. Instead, I took

the Fred Flintstone approach and

shook the hell out of the transmission

by the tail shaft.

All to no avail.

By this time the sun was setting and

the light was fading, so I

admitted defeat and vowed to return

the next day.

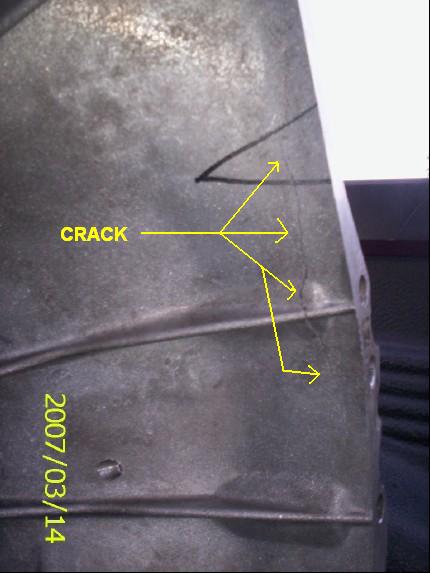

When I got there the next day, I decided

to take the thinking man's

approach (for a change of pace) and

dropped the tranny down.

As I was watching the C6 arc through

its slow descent atop the

floor jack, I was greeted with the

horrifying glint of sunlight passing

through the lovely new crack in the

aluminum transmission case.

I dun broke my tranny case. Way to go Flintstone!

So I did a little postmortem analysis...

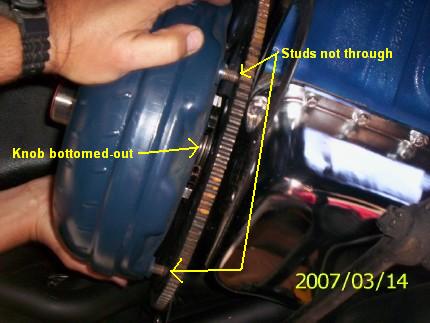

The torque converter had a knob-like

protrusion front and center;

I noticed it before, but it looked

like it would fit into the pocket machined

into the back of the crankshaft. Besides,

that's the one Gil's transmission

gave me to replace the old converter;

I assumed that it was the right one.

Here's how it looked laying on the ground:

I tried to mount the torque converter on the flywheel all by itself:

The knob was too long, so the studs

couldn't poke through the

flywheel. Therefore, I broke the housing

because Gil's gave me the

wrong converter. So I called Gil's,

and they hooked me up with their

aluminum-transmission-case-welding

dude. I had to pay for the

welding, but they gave me a new converter

at no charge.

So, $50 and a few days later, I was back in business.